Contact Us

Service Hotline:

+86 18632090039 (Manager Wang)

+86 13930980503

Mailbox: sales@gaoleihancai.com

Address: No.26 Fuqiang Street, Lutou Collective Economic Reform and Development Experimental Zone, Nangong City, Hebei Province

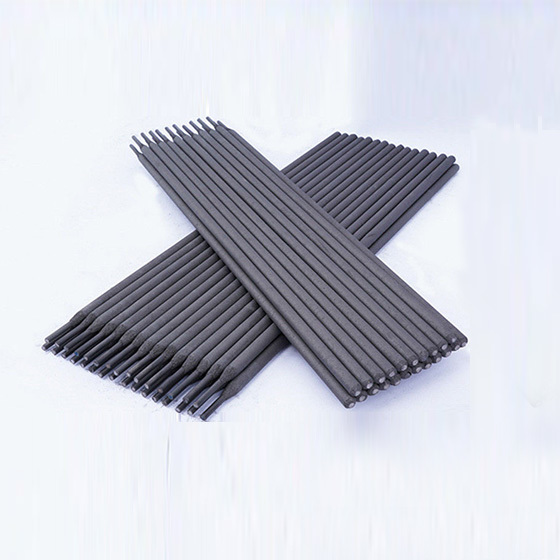

Wear-resistant flux-cored wire

Key words:

Classification:

- Product Description

-

Wear-resistant flux-cored wire is a welding material designed for high wear-resistant and high-strength working environment. It combines the excellent wear resistance of tungsten carbide with the convenience of flux-cored wire to become an indispensable welding solution in many industrial fields. This product adopts advanced production technology to ensure stable welding wire quality and superior welding performance, and provides strong support for the manufacture of various wear-resistant parts.

2. product features

Excellent wear resistance: Tungsten carbide, as a representative of cemented carbide, has extremely high hardness and wear resistance. It is applied to welding wire, so that the welded parts in the face of high-strength wear, can maintain a long service life.

Stable welding process: this product adopts the core design, the chemical composition of the core can be released evenly during welding, ensuring the stability of the welding process and reducing the occurrence of welding defects.

Wide range of applications: tungsten carbide wear-resistant flux-cored wire is suitable for welding a variety of metal materials, such as steel, stainless steel, etc., and is widely used in the manufacture of wear-resistant parts such as mining machinery, construction machinery, and construction machinery.

Environmental protection and energy saving: This product adopts environmentally friendly drug core formula, which produces less harmful gases during welding and meets environmental protection requirements. At the same time, the optimized welding process also helps to reduce energy consumption and realize green production.

3. technical parameters

The main technical parameters of this product include wire diameter, flux core composition, tensile strength, yield strength, etc., all of which meet relevant industry standards and specifications. Specific parameters can be customized according to customer needs to meet the needs of different welding scenarios.

4. method of use

Preparation before welding: clean the welding surface, remove oil, rust and other impurities, to ensure the quality of welding.

Select the appropriate welding equipment: Select the appropriate welding equipment according to the diameter of the welding wire and the welding material to ensure the stability of the welding process.

Adjust the welding parameters: according to the welding material and thickness, adjust the welding current, voltage and other parameters to obtain the best welding effect.

Welding operation: operate in accordance with the requirements of the welding process, maintain the proper distance and angle between the welding torch and the welding surface, and ensure the quality of the weld.

5. considerations

Storage environment: tungsten carbide wear-resistant flux-cored wire should be stored in a dry, ventilated, non-corrosive gas environment to avoid moisture and pollution.

Shelf life: This product has a certain shelf life, please use it within the shelf life. Expired wire may affect the welding effect due to the change of flux core composition.

Safety protection: during the welding process, please wear protective glasses, gloves and other labor protection articles to avoid splash injury.

6. after-sales service

We are committed to providing customers with quality after-sales service, including product consulting, technical support, welding training, etc. If you have any questions or needs, please feel free to contact us and we will serve you wholeheartedly.

The wear-resistant flux-cored wire provides strong support for the industrial field with its excellent wear resistance and stable welding process. We believe that through continuous innovation and improvement, our products will bring more convenience and value to your welding work.

Product inquiry