Contact Us

Service Hotline:

+86 18632090039 (Manager Wang)

+86 13930980503

Mailbox: sales@gaoleihancai.com

Address: No.26 Fuqiang Street, Lutou Collective Economic Reform and Development Experimental Zone, Nangong City, Hebei Province

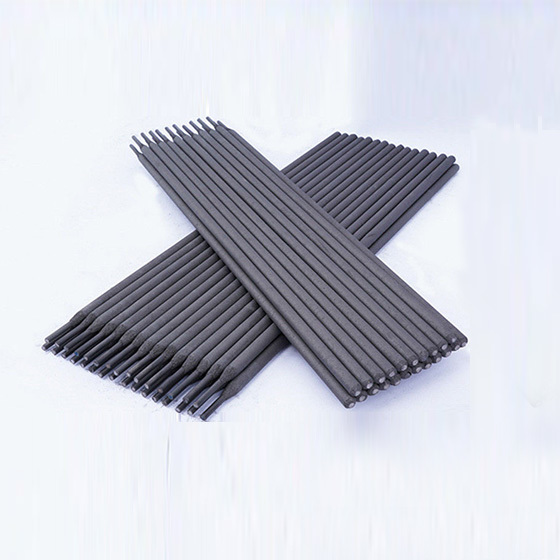

Tungsten carbide alloy electrode

Classification:

- Product Description

-

Tungsten carbide alloy electrodes are a high-performance welding material designed to meet the welding needs of harsh working environments. It adopts advanced production technology, combined with the high hardness of tungsten carbide and the excellent toughness of alloy materials, so as to ensure the strength and wear resistance of welded joints.

2. product features

Excellent wear resistance: The presence of tungsten carbide in tungsten carbide alloy welding rod makes it have extremely high wear resistance and can maintain long-term stability in high friction and high wear environments.

Good welding performance: This product has good welding performance. Whether it is manual welding or automatic welding, it can achieve stable fusion, beautiful welds, and no defects such as cracks and pores.

High strength and toughness: through the reasonable alloy ratio, tungsten carbide alloy electrode in maintaining high hardness, but also has enough toughness, making the welded joint can resist impact and vibration.

Corrosion resistance: tungsten carbide alloy electrode has good corrosion resistance to a variety of chemical media, and can maintain long-term stability in a variety of complex environments.

Strong adaptability: This product is suitable for welding a variety of materials, including steel, stainless steel, cast iron, etc., and is widely used in mining, metallurgy, construction, machinery and other industries.

3. Product Applications

Tungsten carbide alloy electrode is mainly used in the following areas:

Mining machinery: In mining, due to the particularity of the working environment, the wear resistance and strength of the equipment are extremely high. Tungsten carbide alloy electrode can effectively meet these requirements and improve the service life of the equipment.

Metallurgical equipment: The high temperature and high pressure environment in the metallurgical industry poses severe challenges to equipment materials. Tungsten carbide alloy electrode has become the preferred material for metallurgical equipment manufacturing because of its excellent high temperature resistance and wear resistance.

Construction machinery: In construction machinery, tungsten carbide alloy electrodes can be used to weld wear-resistant parts of equipment such as excavators and loaders to improve the durability of equipment.

Mold manufacturing: tungsten carbide alloy welding rod is also widely used in the field of mold manufacturing, which can be used to manufacture high-precision, high wear-resistant molds.

4. method of use

Before use, please make sure that the welding equipment is in good condition, and check the appearance of the welding rod to ensure that there are no cracks, oil stains and other defects.

According to the specific welding process requirements, select the appropriate welding current and voltage.

During the welding process, maintain the appropriate welding speed and angle to obtain the best weld quality.

After the welding is completed, clean up the welding slag and spatter on the surface of the welding seam in time, and carry out necessary post-treatment.

5. considerations

Tungsten carbide alloy electrodes should be stored in a dry, ventilated environment, avoid moisture and direct sunlight.

Wear protective glasses and gloves during use to prevent splashes from hurting people.

If the electrode is found to have quality problems or abnormalities, please stop using it immediately and contact the supplier.

6. product specifications and packaging

Tungsten carbide alloy welding rod has various specifications, and welding rods of different lengths and diameters can be customized according to customer needs. Products using moisture-proof packaging, each box with product instructions and quality assurance.

Summary: As a high-performance welding material, tungsten carbide alloy electrode has been widely used in mining, metallurgy, construction, machinery and other industries because of its excellent wear resistance, good welding performance, high strength and toughness. Through the correct use of methods and precautions, can give full play to its performance advantages, improve welding quality and equipment life.

Product inquiry