Contact Us

Service Hotline:

+86 18632090039 (Manager Wang)

+86 13930980503

Mailbox: sales@gaoleihancai.com

Address: No.26 Fuqiang Street, Lutou Collective Economic Reform and Development Experimental Zone, Nangong City, Hebei Province

Stainless steel flux-cored wire

Classification:

- Product Description

-

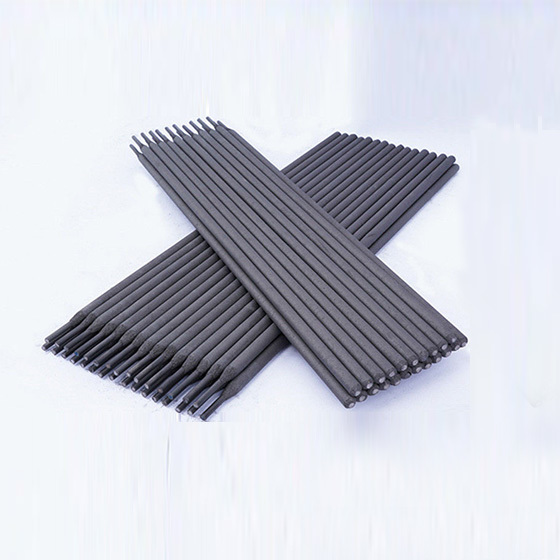

Stainless steel flux cored wire is a high-quality welding material specially used for stainless steel welding. It combines the dual advantages of welding wire and flux. Through the special formula in the flux core, it realizes stable arc during welding, good deposited metal performance and excellent welded joint quality. This product is suitable for welding various stainless steel structures, such as buildings, bridges, chemical equipment, pressure vessels and other fields, and can meet the welding needs under different working conditions.

II. Product Features

Stable arc performance: The stainless steel flux-cored wire adopts a specially designed flux-cored composition to ensure that the arc is stable during the welding process, and it is not easy to produce spatter, which reduces the undesirable factors in the welding process.

Excellent performance of deposited metal: the flux core components in the welding wire are carefully formulated, which makes the deposited metal have good mechanical properties and corrosion resistance, and can meet the welding requirements of different stainless steel materials.

Excellent welded joint quality: By optimizing the core formula and welding process, this product can achieve high strength, high toughness and good crack resistance of welded joints, ensuring the safety and reliability of the welded structure.

Wide applicability: Stainless steel flux-cored wire is suitable for welding a variety of stainless steel types, including austenite, ferrite, martensite, etc., and can meet the welding needs of different fields.

Convenient operability: The appearance of the welding wire is smooth and uniform, and the wire feeding is smooth, which is convenient for welding personnel to operate and improves welding efficiency.

Third, product specifications and packaging

This product has complete specifications and can provide welding wires of different diameters and lengths according to customer needs. The welding wire is made of high-quality stainless steel, and the surface is specially treated to have good oxidation resistance and corrosion resistance. The product adopts moisture-proof and dust-proof packaging materials to ensure good quality during transportation and storage.

IV. Suggestions for Use

Preparation before welding: Before using stainless steel flux-cored wire, ensure that the welding equipment is in good condition and the welding surface is clean and free of oil and oxides.

Select the appropriate welding parameters: According to the thickness and type of welding material, select the appropriate welding current, voltage and welding speed to ensure the stability of the welding process and welding quality.

Pay attention to the welding environment: avoid welding in a humid, windy or dusty environment, so as not to affect the welding quality.

Storage and storage: The welding wire should be stored in a dry, ventilated, non-corrosive gas environment, avoid direct sunlight and long-term exposure to the air.

V. After-sales Service

We are committed to providing customers with quality after-sales service, including product consultation, technical support and after-sales service. If you have any questions or problems, please feel free to contact us, we will be happy to answer and help you.

As an efficient and high-quality welding material, stainless steel flux-cored wire is widely used in the welding field of stainless steel structures. This product has won the trust and praise of the majority of users for its stable arc performance, excellent deposited metal performance and excellent welding joint quality. We look forward to working with you to jointly promote the development and progress of stainless steel welding technology.

Product inquiry